Integrated forms and labels are powerful tools that streamline processes, enhance efficiency, and improve overall business productivity.

The Importance of Integrated Forms in Business

Understanding Integrated Forms

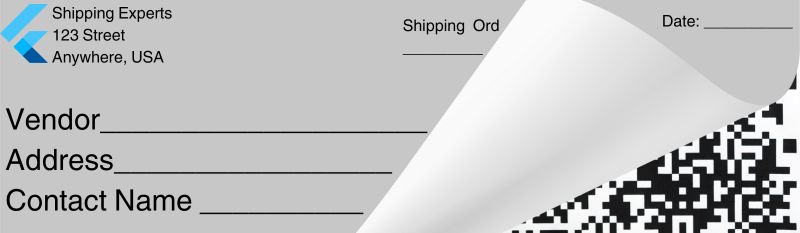

Integrated forms are multifunctional documents that combine labels, forms, and other elements into a single sheet. They are designed to streamline various business processes by reducing the need for separate documents and minimizing the risk of errors. Typically, these forms include sections that can be filled out manually or digitally, along with adhesive labels that can be peeled off and attached to products, packages, or other items. This integration simplifies operations by providing a one-stop solution for data entry, labeling, and documentation.

The Evolution from Traditional Forms to Integrated Solutions

The concept of integrated forms has evolved significantly over time. Traditionally, businesses relied on separate forms and labels for different tasks, which often led to inefficiencies and increased chances of errors. The need to manually match labels with corresponding forms was time-consuming and prone to mistakes. Over the years, the development of integrated forms emerged as a solution to these challenges. With advancements in printing and adhesive technologies, businesses can now utilize integrated forms that combine multiple functions into one cohesive document, enhancing productivity and accuracy.

Key Benefits of Integrated Forms and Labels

The adoption of integrated forms offers several key benefits to businesses:

Reduced Manual Entry: Integrated forms eliminate the need to enter data multiple times across different documents. This streamlines operations and frees up valuable time for employees to focus on more critical tasks.

Minimized Errors: By consolidating information into a single form, the risk of errors caused by mismatched or lost documents is significantly reduced. This leads to more accurate data entry and improved overall reliability.

Enhanced Data Accuracy: Integrated forms ensure that information is consistent and up-to-date across various sections of the form. This consistency enhances data accuracy, which is crucial for making informed business decisions and maintaining operational efficiency.

The transition to integrated forms marks a significant improvement in business processes, offering streamlined workflows, enhanced accuracy, and substantial time and cost savings. Businesses that embrace this innovation are well-positioned to boost productivity and stay competitive in their respective industries.

How Integrated Forms Improve Business Productivity

Streamlining Business Operations

Integrated forms simplify workflows by combining multiple documents into a single, multifunctional form. This integration reduces the complexity of handling various separate documents, ensuring that all necessary information is in one place. By using integrated forms, businesses can streamline processes such as order processing, inventory management, and shipping. These forms can include fields for data entry, adhesive labels, and barcodes, allowing for easy data capture, tracking, and retrieval.

Time and Cost Savings

Integrated forms significantly reduce the time spent on administrative tasks. By consolidating multiple documents into one, employees spend less time searching for, matching, and handling separate forms and labels. This efficiency gain translates into more time for employees to focus on core activities that drive business growth. For instance, a company processing hundreds of orders daily can save substantial time by using integrated forms, leading to quicker order fulfillment and improved customer service.

Cost-Saving Benefits: Reduced Need for Separate Labels and Forms

The use of integrated forms also offers considerable cost savings. By eliminating the need for separate labels and forms, businesses can reduce printing and material costs. Additionally, the streamlined processes result in fewer errors, which in turn lowers the costs associated with rectifying mistakes.

Improved Data Tracking and Management Through Integrated Forms

Integrated forms enhance data management by ensuring that all relevant information is captured accurately and consistently in one document. This consolidation facilitates better data tracking and retrieval, making it easier for businesses to monitor operations and make informed decisions. Integrated forms often include features such as barcodes or QR codes, which further improve data capture and tracking capabilities.

Impact on Decision-Making and Business Intelligence

Accurate and consistent data is crucial for effective decision-making and business intelligence. Integrated forms provide a reliable source of data, enabling businesses to analyze trends, identify areas for improvement, and make strategic decisions based on real-time information. For instance, a logistics company using integrated forms for shipment tracking can leverage the data to optimize routes, reduce delivery times, and improve customer satisfaction. Similarly, a retail business can analyze sales data from integrated forms to forecast demand and manage inventory more effectively.

Integrated forms play a pivotal role in enhancing business productivity by streamlining operations, saving time and costs, and improving data management. Businesses that adopt integrated forms can achieve greater efficiency, accuracy, and operational excellence, positioning themselves for sustained success in a competitive marketplace.

The Versatility of Integrated Labels

Types of Integrated Labels

Integrated labels come in various types, each designed to meet specific business needs.

Common types include:

- Form-Integrated Labels: These combine traditional forms with labels, allowing for seamless data entry and labeling.

- Packing Slip Labels: These include packing information and shipping labels in one document, simplifying the fulfillment process.

- Return Labels: These feature a return form and shipping label, making it easier for customers to return products.

- Barcode Labels: Integrated with forms for inventory management, these labels help in tracking and managing stock.

Customization Options and Their Advantages

Integrated labels offer numerous customization options, such as:

- Size and Shape: Custom labels fit specific products or packaging.

- Adhesive Types: Choose from permanent, removable, or repositionable adhesives based on application needs.

- Color and Design: Custom colors, logos, and designs to align with branding.

- Variable Data Printing: Include personalized information like customer names or unique barcodes.

These customization options provide businesses with the flexibility to create labels that meet their unique requirements, enhance brand visibility, and improve operational efficiency.

Integrated Labels in Various Industries

Integrated labels are versatile tools used across various industries:

Healthcare: Hospitals and clinics use integrated labels for patient records and medication tracking. These labels ensure accurate patient information and improve the efficiency of medical record-keeping.

- Specific Benefits: Enhanced patient safety, reduced administrative errors, and streamlined patient admissions.

Retail: Retailers use integrated labels for pricing, inventory management, and shipping. Labels with barcodes simplify inventory tracking and checkout processes.

- Specific Benefits: Improved inventory accuracy, faster checkout times, and enhanced customer experience.

Manufacturing: Integrated labels in manufacturing help with product tracking, quality control, and shipping. Labels with QR codes provide detailed product information and ensure traceability.

- Specific Benefits: Better product traceability, improved quality control, and efficient shipping processes.

Enhancing Branding and Marketing

Integrated labels are powerful tools for branding and marketing. By incorporating logos, colors, and brand messages, businesses can create a cohesive brand identity. Labels can also include promotional messages, discounts, or QR codes that lead to marketing campaigns or product information.

Examples of Successful Branding Strategies Using Integrated Labels

E-commerce Company: An online retailer used integrated packing slip labels that included their logo, brand colors, and a QR code leading to a discount page. This strategy not only enhanced the unboxing experience but also encouraged repeat purchases.

Food Manufacturer: A food manufacturer integrated nutritional information and branding elements into their product labels. The visually appealing labels helped build brand recognition and trust among consumers.

Cosmetic Brand: A cosmetic brand can use integrated return labels with their branding and a personalized thank-you note. This approach improves customer satisfaction and reinforces brand loyalty.

The versatility of integrated labels makes them an essential asset for businesses across various industries. Their ability to streamline operations, enhance branding, and improve customer experience highlights their value in today’s competitive market.

Implementing Integrated Forms and Labels in Your Business

Steps to Successful Implementation

Assessing Your Business Needs

The first step in implementing integrated forms and labels is to assess your business needs thoroughly. Identify the areas where integrated solutions can bring the most significant improvements, such as inventory management, order processing, or customer service. Consider the specific challenges your business faces and how integrated forms and labels can address these issues. Conduct a detailed analysis of your current processes to pinpoint inefficiencies and potential areas for improvement.

Choosing the Right Integrated Form and Label Solutions

Once you’ve assessed your business needs, the next step is to select the appropriate integrated form and label solutions. Consider factors such as the types of forms and labels required, customization options, and compatibility with existing systems. Work with a reputable integrated form equipment provider like Tamarack® Products to ensure that the solutions you choose are designed to your specific requirements. Evaluate different options and select the ones that offer the best combination of functionality, quality, and cost-effectiveness.

Overcoming Common Challenges

Implementing integrated forms and labels may come with certain challenges, such as resistance to change, integration with existing systems, and initial costs. To overcome these challenges:

- Resistance to Change: Engage employees early in the process, clearly communicate the benefits, and provide training to ensure a smooth transition.

- Integration with Existing Systems: Work with IT and operational teams to ensure compatibility and seamless integration with current software and processes.

- Initial Costs: Highlight the long-term cost savings and efficiency gains to justify the initial investment.

Tips for a Smooth Transition

- Pilot Testing: Start with a pilot program to test the integrated forms and labels in a controlled environment. Gather feedback and make necessary adjustments before full-scale implementation.

- Employee Training: Provide comprehensive training for employees to familiarize them with the new forms and labels, ensuring they understand how to use them effectively.

- Continuous Support: Offer ongoing support and resources to address any issues that arise during the transition period, ensuring a smooth and successful implementation.

Measuring Success

Key Performance Indicators to Track

To measure the success of integrated forms and labels, track key performance indicators (KPIs) such as:

-

- Process Efficiency: Monitor the time taken to complete tasks and compare it to pre-implementation levels.

- Error Rates: Track the number of errors in data entry, labeling, and processing before and after implementation.

- Cost Savings: Calculate the reduction in costs associated with printing, materials, and error rectification.

- Customer Satisfaction: Measure improvements in customer satisfaction through feedback and surveys.

Continuous Improvement and Optimization Strategies

-

-

- Implement a continuous improvement approach to optimize the use of integrated forms and labels. Regularly review KPIs, gather feedback from employees and customers, and identify areas for further enhancement. Stay updated with the latest advancements in integrated form and label technologies to ensure your business remains competitive and efficient.

-

Integrated forms and labels offer significant benefits, including streamlined business operations, time and cost savings, and enhanced data management. These solutions simplify workflows, reduce errors, and improve overall productivity, making them a valuable asset for businesses across various industries.

Explore the potential of integrated forms and labels to boost your business productivity.

Tamarack Products: Over 50 Years of Expertise

Tamarack® Products has been a pioneering force in the field of inline integrated labeling equipment since the inception of integrated labels. Founded with a commitment to innovation and quality, Tamarack has built a reputation for designing, engineering, and manufacturing advanced labeling solutions that meet the diverse needs of businesses across various industries. Our extensive experience and expertise have positioned us as a trusted partner for companies seeking reliable and efficient labeling equipment.

The Tamarack MVW Inline Integral Labeling Equipment

One of our flagship products, the Tamarack MVW Inline Integral Labeling Equipment, exemplifies our commitment to innovation and quality. The MVW INLINE is designed to integrate seamlessly into existing production lines, providing a versatile and efficient solution for various labeling needs. Here are some key features and benefits of the MVW INLINE:

-

-

-

- High-Speed Labeling: The MVW INLINE is capable of high-speed operation, ensuring that production lines run smoothly and efficiently without bottlenecks.

- Versatility: This equipment can handle a wide range of label types and sizes, making it suitable for diverse applications across different industries.

- Precision and Reliability: The MVW INLINE offers precise label placement and adherence, minimizing errors and ensuring consistent product quality.

- User-Friendly Interface: With an intuitive interface, the MVW INLINE is easy to operate, reducing the need for extensive training and allowing for quick setup and adjustments.

- Durability: Built with high-quality materials and robust engineering, the MVW INLINE is designed for long-term reliability and minimal maintenance.

-

-

At Tamarack, our customers are at the heart of everything we do. We understand that each business has unique needs, and we strive to provide customized solutions that drive success. Our comprehensive support services, including installation, training, and maintenance, ensure that our clients can maximize the benefits of our equipment. We are dedicated to building lasting partnerships and helping our customers achieve operational excellence through innovative labeling solutions.

With over 50 years of experience, Tamarack Products continues to lead the way in integrated labeling technology. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry. Let us help you achieve operational excellence with our innovative solutions customized to your unique needs. Contact us to learn how Tamarack’s integrated form solutions can transform your business operations and drive productivity.