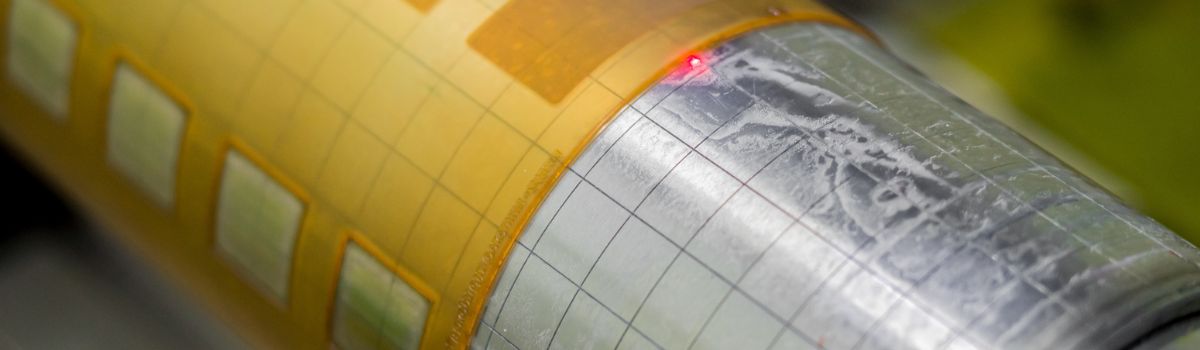

Flexography is one of the most rapidly growing types of printing processes in use today, with three different types of Flexo printing commonly used in the packaging industry today:

- Narrow web

- Mid web

- Wide web

Narrow Web Flexo Printing

Narrow web Flexo printing presses typically range up to 18” or less in width and are a good solution for small print runs. Narrow web printing is usually more accessible to smaller companies that want labels or other items printed in small quantities. It can be challenging for small and mid sized manufacturers to determine the right printing options when many large companies focus on high-volume print runs which are not feasible for small companies.

The narrow web printing options are also better for smaller companies that may not be able to purchase the large amount of stock that is required of wide web processors. Narrow web Flexo printing is common in many printing applications such as printing labels, poly bags, and flexible packaging items.

Mid Web Flexo Printing

Mid-web Flexo printing satisfies printing needs typically in the range of 22” to 40” in width and can help to satisfy requirements for markets in transition between narrow and wide web printing. Narrow and wide web have been the two most popular types of Flexographic printing, although mid-web printing has been established as a solid niche between the two as companies worldwide are altering the way they do business and insisting on more options.

There has been an increase in using mid-web Flexo printing for the packaging industry with the main driver being the options for increased width, to print on a wider web at higher speeds for increased productivity.

Wide Web Flexo Printing

Wide web Flexo printing typically involves printing on larger substrates that are at least 40 inches wide and is used for higher volume print jobs where a large amount of material must be processed. Wide web printing is used for large applications such as large trash bags or flexible packaging that can later be cut into smaller packages like pouches and bags. Many brands prefer wide web printing due to high speed and cost-effective stickers, decals, and large signs.

The biggest advantage of wide web printing is the speed at which large printing projects can be completed. Wide web printing provides solutions with fast and efficient high-volume printing processes and is typically used for simple projects with just a few colors and images that are not too complex. The speed at which the Flexo printing machine operates directly impacts ink distribution and drying time.

Wide web printing performs better with ink that dries faster such as UV curing types of ink. Your Flexo printing press manufacturer can help you to determine the best type of ink to use for your project, whether water-based or UV Flexographic inks.

Tamarack® Products Offers Flexographic Printing Solutions

Tamarack® is a leading manufacturer of web finishing systems with more than 50 years of experience in customizing in-line and offline integrated labeling solutions. The P500 in-line integrated labeling system on a Flexo press easily affixes laminates, transfer tapes, holograms, scratch-off materials, and more to satisfy the needs for various integral and integrated forms, cards, and labels. With servo-driven technology, the P500 easily integrates into your press for inline Flexo printing in widths ranging from 13” to 20”, and speeds up to 500 ft/min.

Tamarack® is an industry leader in web finishing equipment, offering high-quality, reliable and accurate solutions with custom engineering available. Experience the Tamarack difference to achieve higher productivity and profitability with our commitment to excellence and in-depth industry expertise. Contact us to learn more about the most efficient and cost-effective web printing solutions for you.