Narrow web flexo printing is a dependable and cost-efficient solution for companies producing mid-large print production runs. Narrow web flexo printing eliminates the requirement for additional drying time when using UV-curable inks that have a fast dry time, providing a low ink cost without affecting the image quality.

People are often confused about how printers print when using varying substrate sizes. With flexo printing, you can print using narrow, mid, and wide web. Many businesses choose narrow web printing because it requires less space while still producing fast, quality printing runs.

Narrow Web Printing Applications

Many different industries rely on narrow web printing to produce high-quality, photogenic quality prints including commerce, retail, transport, pharmaceutical, chemicals, steel, and agriculture. The quality of print ensures cohesive brand imaging by producing the exact color and imagery of a company’s logo, slogan, etc.

Food Packaging Industry

Narrow web printing is safe for packaging food products, making this process widely used in the food packaging industry on materials such as packet sleeves and sachets in addition to more specialized items like coffee cups. Due to the smaller web, narrow web printing is appropriate for printing smaller details such as ingredients or instructions without the risk of smudging or the text appearing blurry.

Sticker and Label Applications

The most produced item for narrow web printing is self-adhesive labels. This allows several in-line processes to work together and produce single-layer or multi-layer labels.

Ticket Applications

Many industries rely on the use of tickets for their company to drive revenue. Items such as concert tickets, parking tickets, tickets required for traveling, and other special event tickets are commonly produced on narrow web printing equipment.

The unique component of printing tickets is that no two are usually identical, whether the ticket number, date, or other information is slightly different from ticket to ticket.

Tickets provide unique challenges when printing, for example:

-

-

- Tickets must be legible, even if the ticket is small and a compact font is required. Oftentimes, a ticket used for entry to an event cannot be smudged or look like it was tampered with, or it will invalidate the ticket.

- Identifying numbers or codes must be printed accurately on each ticket, so a versatile printing method would be needed for mass production.

-

Other tickets must have specific information printed for Point of Sale, so specific thermal coating is required Narrow web flexo printing offers the flexibility to modify the information for each item while still being cost-effective and efficient.

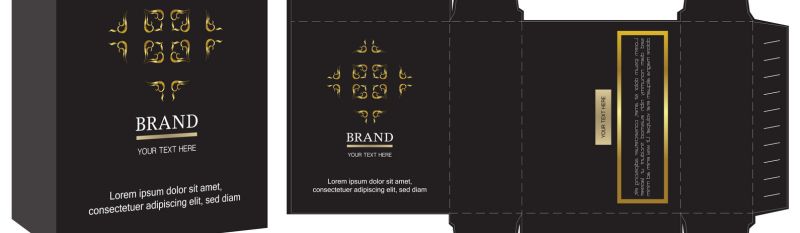

Carton Applications

Narrow web flexo printing is ideal for companies looking for very small text to be printed on lightweight cartons because, in a single pass, the carton can be printed, creased, and cut. Generally, this type of carton is used for packaging by pharmaceutical companies.

Narrow web presses require less space because they print on smaller substrates, so they are ideal for businesses that have limited space for printing presses. The focus of narrow web flexo printing is high-quality, fast printing on a smaller scale.

Tamarack® Products delivers innovative web finishing solutions and is recognized as an industry leader with over 50 years of experience. Tamarack® offers versatile web finishing equipment like the servo-driven Versa Web P500 that can be integrated with new equipment or into your current printing press and has offline and inline options to choose from.

Tamarack® Products offers custom web finishing equipment that is modular and scalable to meet the unique needs of your business. We have over 50 years of experience in designing, manufacturing, and engineering top-quality specialized equipment for the packaging, label, and business forms industries. Contact us to learn how we can help improve your business’ narrow web printing processes.